Logistics

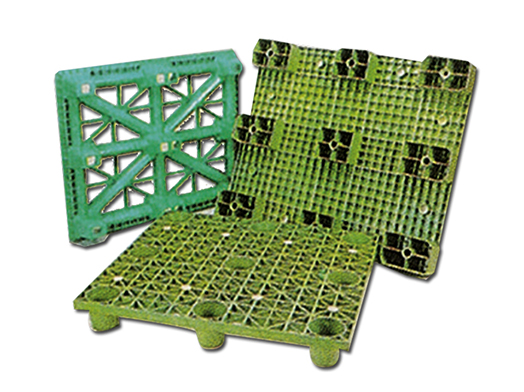

Pallet and crate are major carrier of transportation for sending goods to destination. Considering to save cost, nowadays plastic pallet and crate are popular used when goods shipped overseas. However, the investment for the molding machine is huge. Imagine how big is the molding machine to produce a 25kg pallet or 40kg pallet box? 3000 ton to 4000 ton is required. However, making a big machine is not buying standard parts from outside and assembly. It takes proof over long time, and long term relability test.

Furniture

Plastic chair, sofa, and drawers provide economic goods for the emerging markets and every one can easily afford for the product. Thin Wall Houseware is now another trend for high end market. Light weight and fancy design create another line for furniture.

CF Series

TP Series