SEW/ES

SEW/ES

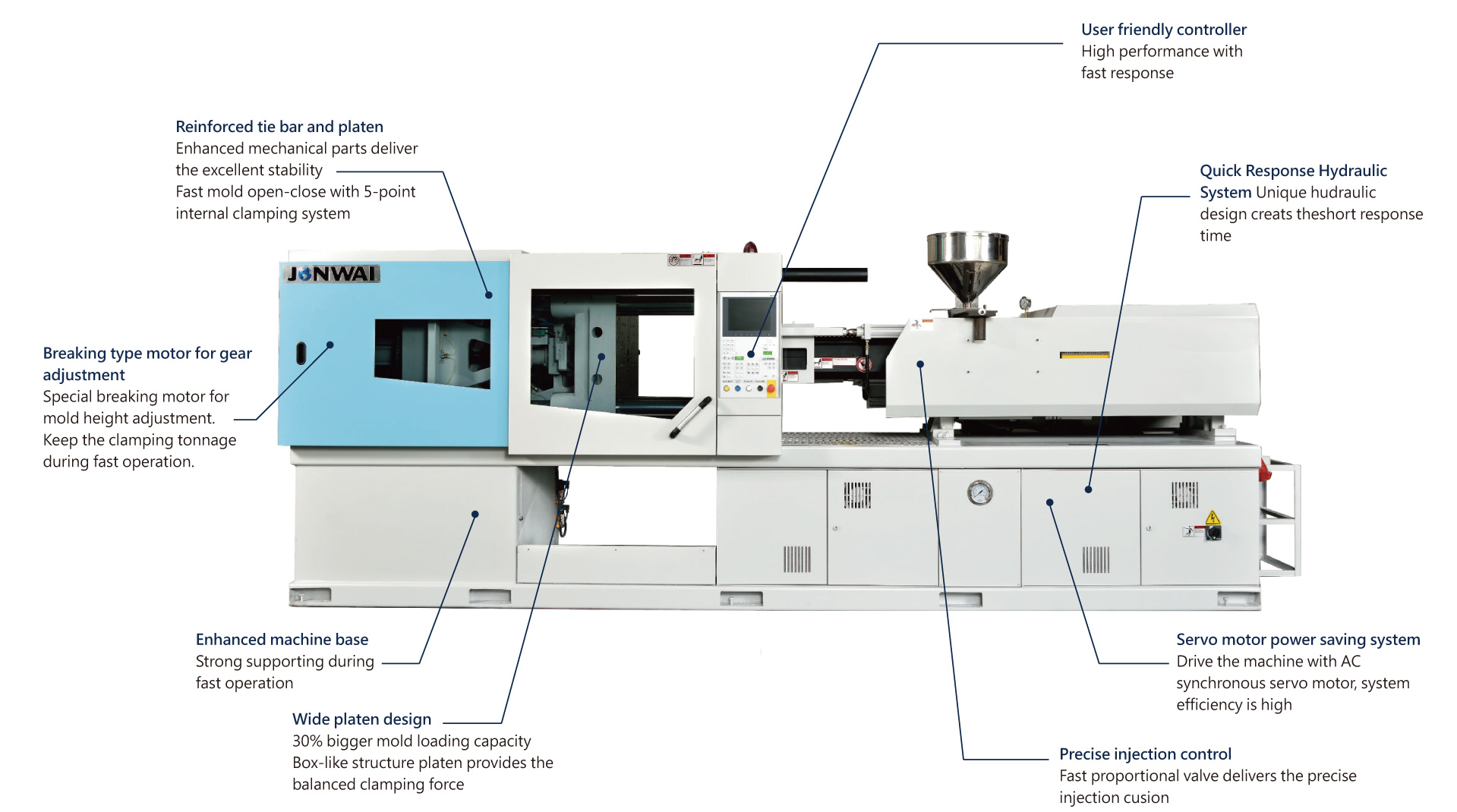

SEW / ES系列機型是曲手的鎖模機構搭配寬板的設計

- 精準的射出控制

- 生產能達到低不良率

- 寬板的機壁設計能增加30%的容模量

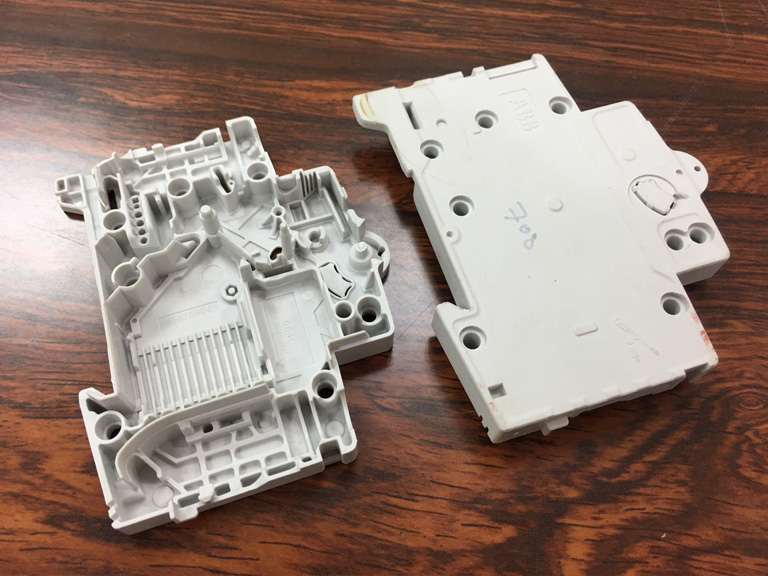

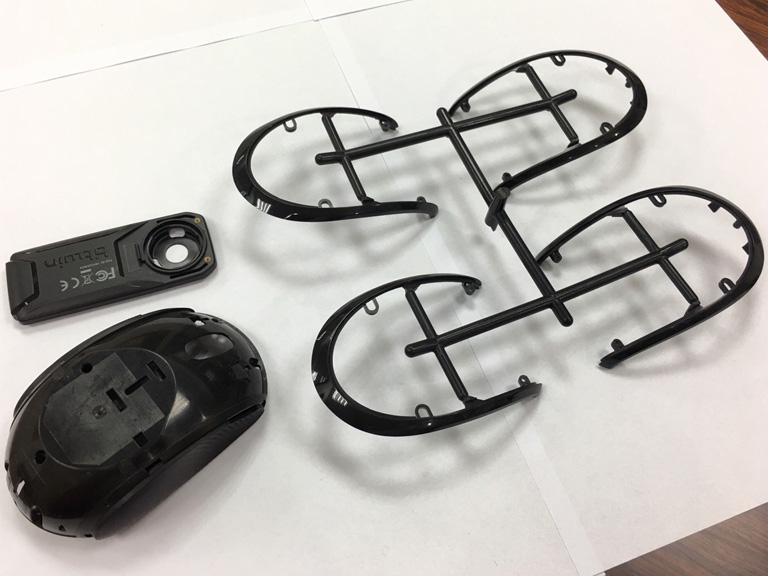

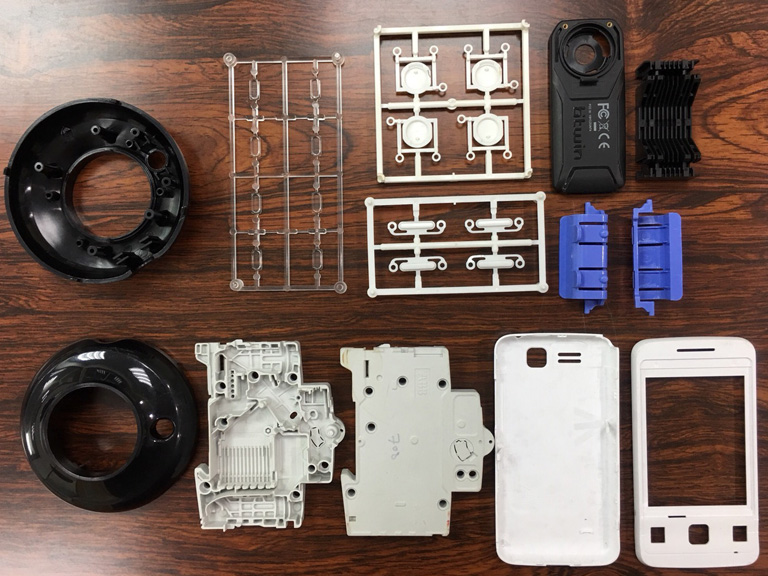

- 適合電子零件、醫材、車用零配件、家電與家用品生產

| Model Name | Unit | 120ES | 150SEW/ES | 200SEW/ES | 250SEW/ES | 300SEW/ES | 400SEW/ES | 500SEW/ES | 600SEW/ES |

|---|---|---|---|---|---|---|---|---|---|

| Clamping Tonnage | tons | 120 | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

| Tie bar distance (WxL) | mm | 460 x 380 | 510 x 410 | 580 x 480 | 620 x 520 | 730 x 580 | 810 x 630 | 880 x 720 | 960 x 820 |

| Platen size (WxL) | mm | 660 x 580 | 720 x 620 | 830 x 730 | 890 x 790 | 1020 x 870 | 1130 x 950 | 1230 x 1070 | 1340 x 1200 |

關於 SEW

SEW 機器特色

強化機構

- 支柱應力形變降低20~25% 增加耐用度

- 曲肘面壓降低20~40%提高強度以增加曲肘壽命

- 強化曲肘布司及軸心可降低磨耗增加使用壽命

- 模板重新設計以降低模板變形量約25%並使模具受力均勻

- 模板加寬及模厚加大增加容模量達20~25% 可靈活使用各種模具

- 320~530TON機種加大開模行程

全新油路設計

- 獨立油壓導引控制系統

- 曲肘自動定量容積式潤滑

- 採低噪音高效率幫浦與壓力比例油壓系統以提高成型精度與穩定度

同步伺服電機省電系統

- 採用歐洲知名品牌變頻器

- 採齒輪幫浦以達高響應, 低噪音且易於維護

- 速度閉迴路控制實現良好精密度與穩定度

- 內建直流電抗與RFI濾波器避免干擾

SEW 優點

Design For Precision Molding

Fast response, user friendly controller

Our powerful controller can run multiple tasks under high operation speed. With friendly interface, user can set the parameters and monitoring production easily.

Sensitive hydraulic circuit

We install Vickers, Tokimec, Yuken valves on machines. The unique hydraulic design reduces 20% dry cycle time.

Precision injection cusion

With sensitive hydraulic design and fast response servo motor, we can control the injection cusion precisely and maintain exact product shot weight.

Advanced electrical protection

Unstable voltage might damage Controller and electronic parts. We install upgraded inverter to drive the system and equip CT, MCB and fuse to avoid any damage from unstable current.

Flexible of Production

The innovation of mold technology improving constantly in decade. With the new valve gate and hot runner design, the required clamping tonnage reduced. It means the same mold can run on the smaller tonnage machine. However, due to the mold loading capacity, customer needs to load the mold on the big machine. The machine is over spec of production.<br />SEW has wide platen design that increases 30% mold loading capacity. The same mold can run on the smaller machine. Customer can also run the same tonnage machine with more cavity. The production is more flexible. There are several advantages of our wide platen machine.

High Ouput

The dry cycle of smaller tonnage machine is faster.

The output will increase.Low power consumption

Smaller machine has lower running cost. And saving is earning.

Less investment

Buying a smaller machine instead the big one, the budget will be less.

Shorter payback period

Lower investment and running cost can make the higher output. It is absolutely a good solution for customer.

Low Running Cost

High efficiency servo drive

Servo motor works with inverter, the power consumption can save 30 to 70% compare to traditional motor.

Electric charging system

Charging by electric motor has high efficiency. Compare to hydra motor, electric charging system can save another 20% power consumption.

Customized features

- Injection sequencial control (mold with valve gates)

- Fly core/eject

- Fly charging

- Electric charging system

- Bi-metallic screw and barrel for engineering material

- Unscrew device